Existing wooden formworks are fixed by applying rebars and nails on the panel and lumber to install and dissemble. In this course, the formworks are damaged and become not suitable for recycling. In addition, the nails and iron materials used to fix the formworks are buried and discarded in the soil after the construction.

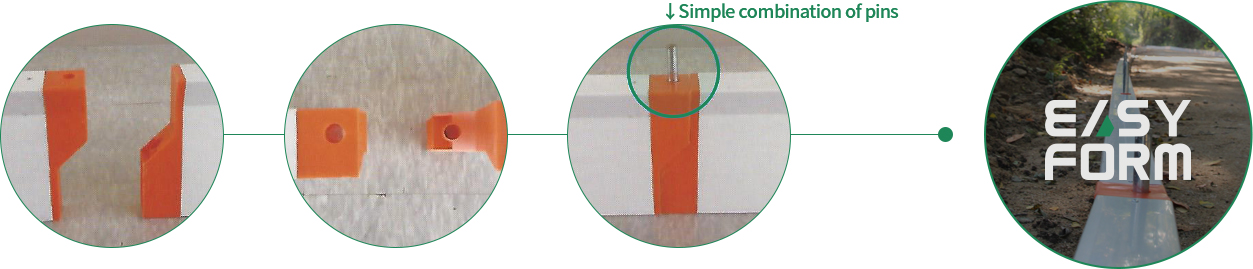

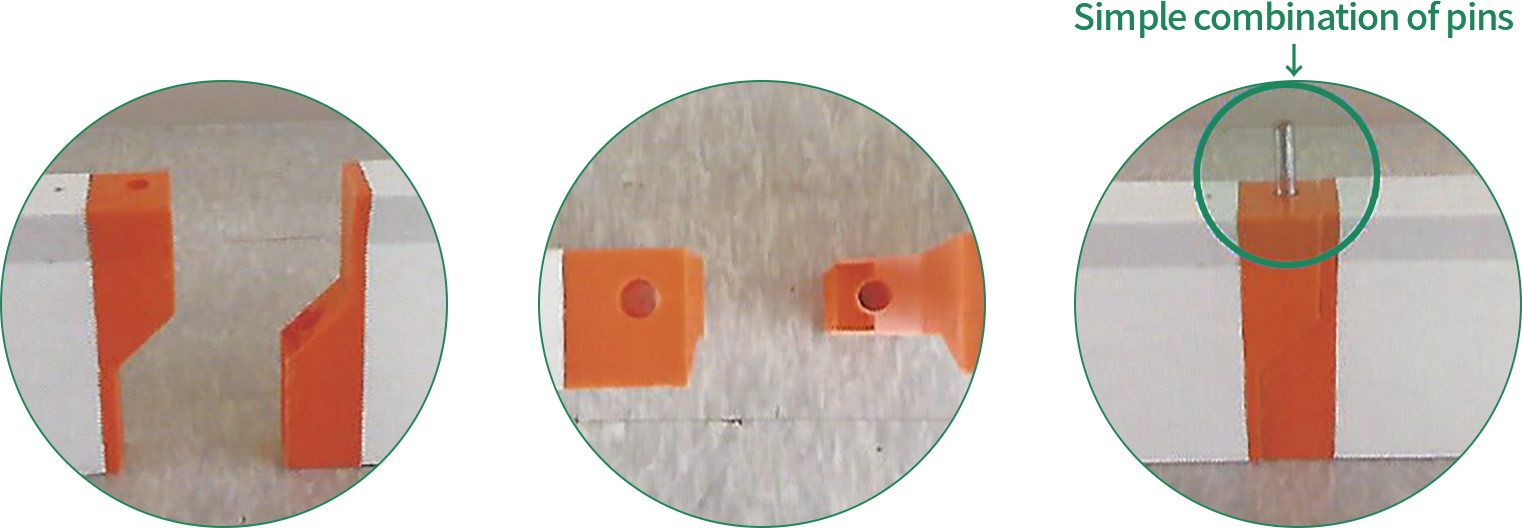

Also, the formworks apply separating compound on the face so that the panel can be detached from the concrete easily. This incurred soil pollution from the compound when raining. Those supplementary materials to fix the formworks also affected to the construction period and are the hindering factor in saving the cost. Easy Forms are eco-friendly as they are molded synthetic resins and can be detached from concrete easily as well as not using separation compound. As they are fixed on the ground via fixing pins to each end, it is speedier to install and dissemble them, helping to save labor cost a lot. As the fixing pins are applied and separated easily, they do not harm the form, which can be re-used up to 50 to 60 times. Also, the form does not need specialized manpower which is the big junk of the cost savings focus, making the form much more economical.

-

STEP1Installation of Easy Form

STEP1Installation of Easy Form -

STEP2Depositing concrete and face work

STEP2Depositing concrete and face work -

STEP3Dissembling Easy Form

STEP3Dissembling Easy Form

-

Advantage 01Easy installation

Even a beginner can install and assemble them.

Points

01 -

Advantage 02Short work time

Speedier installation than current work process.

(Around half of existing work.)Points

02 -

Advantage 03Superb economics

Reduces labor cost and work process, resulting in a great cost saving.

Points

03 -

Advantage 04Convenience

Transportable on a one-tonnage truck up to 350 M and can be used semi-permanently.

Points

04

-

Construction and civil engineering

-

Agricultural road concrete construction

-

General and specialized engineering

-

Local government roads including city

-

County, and forest roads

-

Various road constructions and foundation works

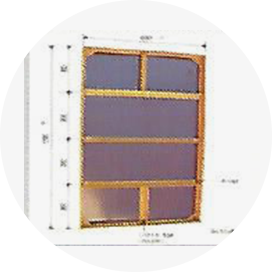

| Classification | Easy Form | Existing products | |

|---|---|---|---|

| Material | Synthetic resin | Metal | Wooden panel |

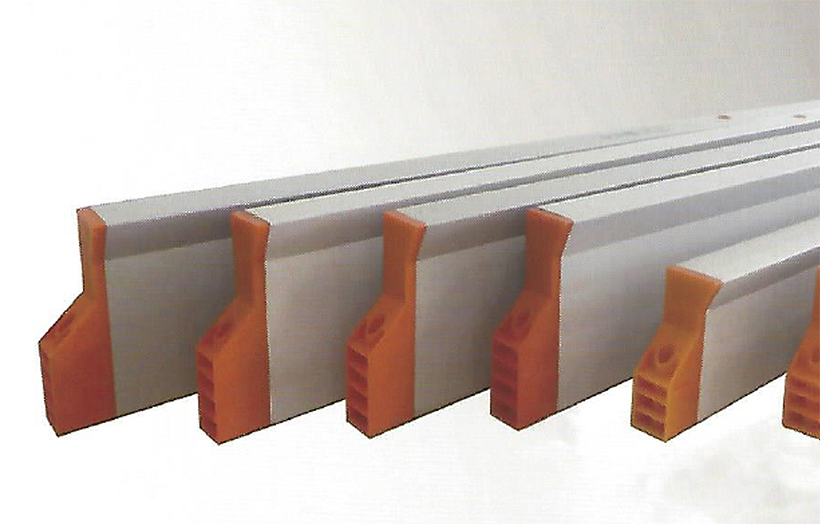

| Size | 2000mm x 200mm x 45mm | 1200mm x 200mm x 35mm | |

| Form |  |

|

|

| Weight | 4.3kg | 11kg | 8kg |

| Convenience of installation | Very convenient (fixed by pins) | Inconvenient (should support the panel) | Very inconvenient (should make double supports) |

| Re-usability | Almost no damage from installation and dissembling | Needs to replace the pane regularly | The wool is highly likely to be spoiled or damaged during the process of installation and dissembling. |

| Economics (labor cost) |

Needs 2 men a day for 350 M installation. | Needs 4~5 men a day for 350 M installation. | Needs 5~6 men a day for 350 M installation. |

| Economics (transportation) |

Needs one 1.5 tonnage truck for 350 M installation. | Needs three 1.5 tonnage trucks for 350 M installation. | |

| Eco-friendly | Eco-friendly as they do not need separating compound and supplementary materials. |

Wooden panels need separating compound to prohibit them from attaching to the concrete. The compound is harmful for human body and absorbed into the soil when it rains. |

|

You can also easily uninstall just by removing the pins which dissembles the formwork.